Ball valve gearboxes are critical components in many industrial applications, providing the necessary mechanical advantages to operate ball valves efficiently. These gearboxes are designed to handle the high torque required to turn ball valves, which are often used to control the flow of fluids or gases in a system. In this article, we will explore the function and importance of ball valve gearboxes in various industries.

Ball valve gearboxes are commonly used in industries such as oil and gas, petrochemical, water treatment and power generation. In these industries, ball valves are used to regulate the flow of fluids in pipelines, tanks, and other process equipment. Ball valve gearboxes are critical to ensuring the valve operates safely and reliably even under harsh operating conditions.

One of the key functions of a ball valve gearbox is to provide the mechanical advantage needed to turn the ball valve. Ball valves are designed with a spherical closing element that typically operates with a quarter-turn movement. This requires a lot of torque, especially for larger valves or those subject to high pressure or temperature. The gearbox is responsible for amplifying the input force from the handwheel or actuator so that the valve can be operated easily.

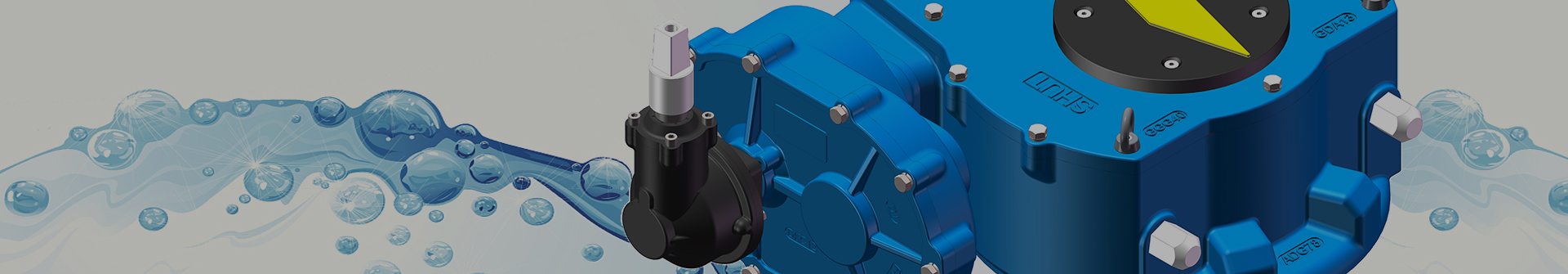

In addition to providing mechanical advantages, ball valve gearboxes also provide a degree of control and precision in valve operation. Many gearboxes are equipped with features such as adjustable stops and position indicators that allow operators to accurately position the valve and control the flow of process fluid. This level of control is critical for industries that require precise flow regulation to ensure safety and efficiency throughout the process.

Another important aspect of ball valve gearboxes is their ability to withstand harsh operating conditions. In industries such as oil and gas, petrochemicals and power generation, valves are frequently exposed to high temperatures, pressures, corrosive chemicals and other challenging environments. Ball valve gearboxes are designed to withstand these conditions, often with rugged construction and materials that can withstand extreme temperatures, corrosion and mechanical wear.

It’s also worth mentioning that many ball valve gearboxes are designed to be easy to maintain and repair. This is important in industries where downtime is costly and any equipment failure can have far-reaching consequences. The gearbox’s modular design and easily replaceable parts make it easier for maintenance personnel to inspect, repair and replace parts as needed, ensuring the valve remains operational and reliable.

In summary, ball valve gearboxes play a vital role in the operation of ball valves in various industrial applications. They provide the necessary mechanical advantages, control and reliability to ensure ball valves can operate safely and efficiently under demanding conditions. With their rugged construction, precise control capabilities and ease of maintenance, ball valve gearboxes are important components in industries where regulation of fluid or gas flow is critical.

Post time: Dec-09-2023